Fertiliser Spreader – GET READY FOR NEXT SEASON

Helpful tips and tricks to get your Fertiliser Spreader prepared to operate at its maximum capacity through the season.

Contact your local Kverneland dealer to arrange a pre-season service or health check on your Kverneland Fertiliser Spreader to ensure it delivers the best performance and maximises crop yields.

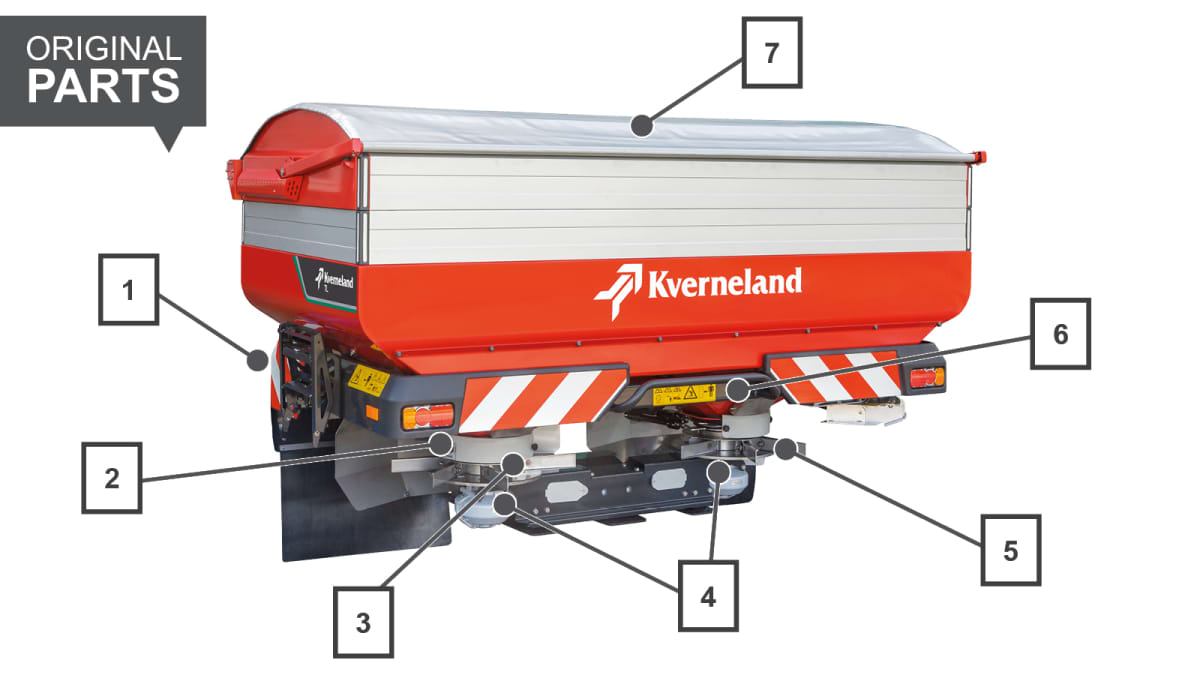

Check safe working condition of PTO shaft and guards.

Lubricate and replace any faulty parts.

Check dosing cup settings. Reset if necessary

Check all drive shafts & clutch discs.

Replace worn parts

Check oil levels in both gearboxes

– top up if required

Inspect all spreading vanes – replace if worn or damaged

Ensure all actuators and weigh cells are free of fertiliser residues

Ensure the hopper is clean and free of any blockages

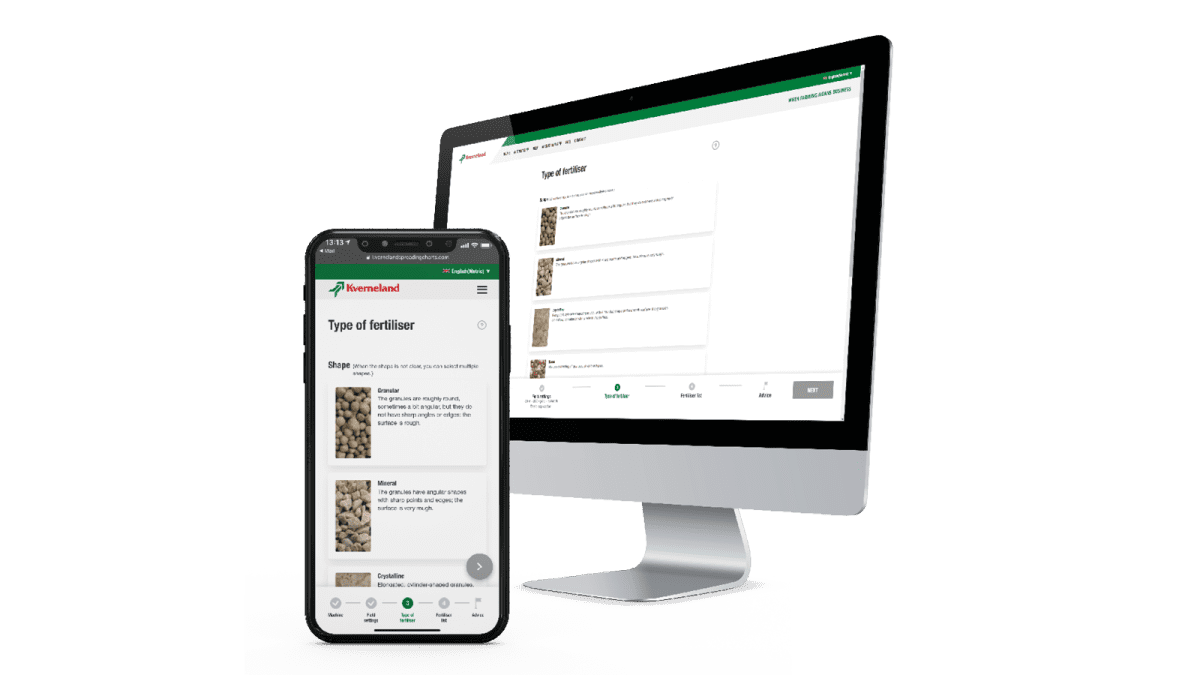

The key to precise spreading is matching fertiliser quality and litre weight with the spreading charts as close as possible.

The Kverneland Fertilizer Spreader checklist helps you to ensure consistent accuracy in all field conditions.

1. Select fertiliser type.

2. Determine granule size and distribution.

FERTILISER SHAKERBOX

VN79771219

3. Determine litre weight

MEASURING CUP

VNB3405278

WEIGHT SCALE 50KG

AC353924

Get direct access to the spreading charts!

The spreading charts application is available on the App store and Google play

Also available online!

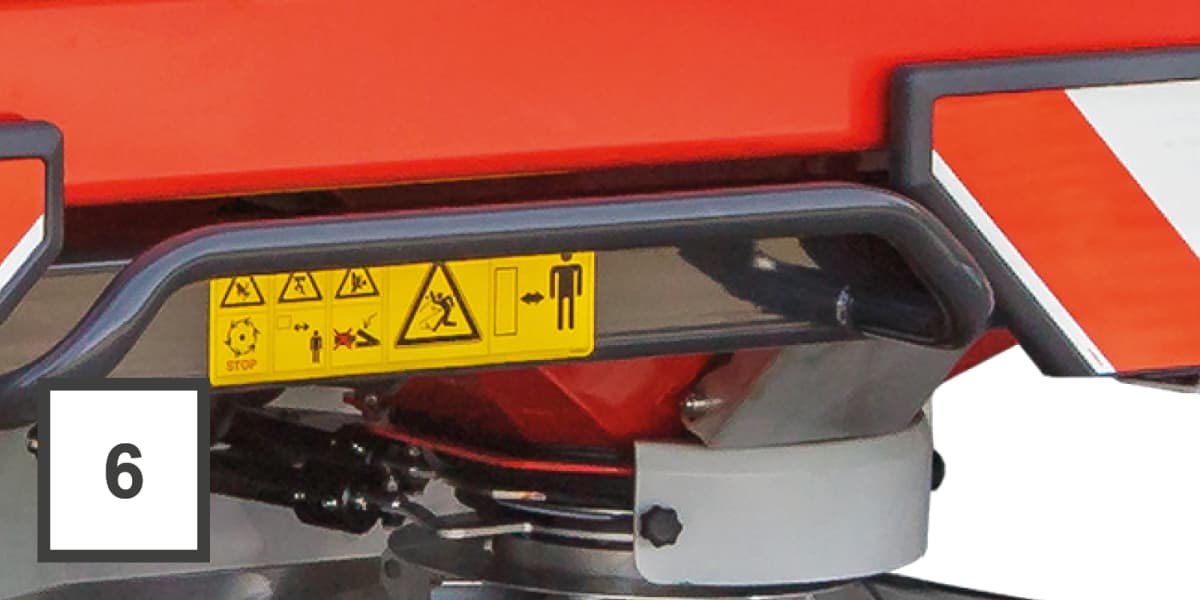

Fertiliser can be hard on your machine and often causes aggressive corrosion.

The special Kverneland Group winter wax coating protects all metal parts and weigh cells against corrosion – and ensures your Fertiliser Spreader remains in top working condition.

WINTER COATING

A138672101

Each disc on your Kverneland Spreader has an actuator to adjust and control the discharge point. With the setting tool and elastic rope you are in full control over each section of your spreader.

SETTING TOOL

VNB1709302

ELASTIC ROPE

VNB1754278

Original vanes from Kverneland are always the safe choice for your Kverneland Disc Spreader. Our vanes are designed and manufactured to a uniformly high standard, ensuring the reliability of your machine, and guaranteeing that you’ll always achieve the results as promised.

EXACTA HL / TL / TL GEOSPREAD

A138361730(12 pcs. Including lock nut)

EXACTA HL / TL / TL GEOSPREAD

A148715730(12 pcs. Including lock nut)

EXACTA TLX GEOSPREAD

A148715830(16 pcs. Including lock nut)

EXACTA-EL

A138361430(12 pcs. Including lock nut)

EXACTA-CL / CL-EW / CL GEOSPREAD

A138361530(16 pcs. Including lock nut)

EXACTA HL / TL / TL GEOSPREAD

A138361630(12 pcs. Including lock nut)

EXACTA TLX GEOSPREAD

A138613630(16 pcs. Including lock nut)

EXACTA HL / TL / TL GEOSPREAD

A148656730(12 pcs. Including lock nut)

EXACTA TLX GEOSPREAD

A148666630(16 pcs. Including lock nut)

Time is money, and we know the importance of receiving the right parts at the right time! Your Kverneland dealer is supported by a massive distribution network to supply you with exactly what you need, when you need it.

Our main distribution centre Metz warehouse is located in Thionville, France. A strategic location for distributing parts to all corners of the world. With over 70.000 parts in stock and 24/7 service, we are ready to supply you with parts – at any time!